Tackle massive construction equipment tires – safely and easily

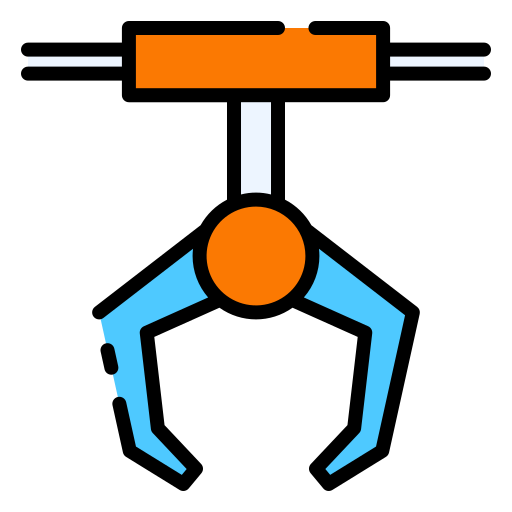

Introducing the TireGrabber – making handling and changing tires on the construction site effortless.

Construction deadlines are unforgiving. The need to change tires on an articulated truck, asphalt paver, backhoe, dump truck, telehandler, forklift loader, grader can bring everything to a screeching halt. The TireGrabber is the patented industrial tire manipulator you need to tackle massive construction equipment tires safely and efficiently, no matter the job site.

Revolutionize large-scale tire handling on the construction site

Effortless management of oversized tires

The TireGrabber’s innovative three-arm gripper attaches to any hydraulically equipped machine and offers extended reach for secure mounting, dismounting and rotation of large construction tires up to 12,000 lbs (5 443 kg).

Prioritizing safety

Traditional methods of handling large tires using pallets, straps and chains are often dangerous and pose a risk of injury. The TireGrabber prioritizes safety for your crew by offering a clean, simple way to handle heavy, large-scale tires from a safer distance with fewer workers required – thus minimizing the risk of injuries.

Avoid costly delays

One operator can handle massive industrial tires in record time with the TireGrabber, eliminating the need to pull a team off the worksite for tire-changing duty and keeping your construction projects on track.

Precise tire-changing control

The 45-degree, 3-arm rotating gripper securely grabs industrial tires to provides a tight hold, allowing for effortless maneuvering, perfect alignment, and balanced tire handling – making even the toughest construction site tire changes a breeze.

Longer tire life. More savings.

Regular tire rotations are crucial for maximizing tire life and minimizing replacements on your expensive construction equipment. The TireGrabber makes this process quick and easy, saving you money on tires, time and resources.

Built to withstand the toughest jobs

The TireGrabber is constructed with high-strength, tensile steel and is rigorously tested (including a magnetic particle inspection) to ensure durability and performance in demanding construction environments. Choose from five models to perfectly suit your specific needs:

TG3000

Handles tires from 54″ to 89″ (1 372 mm – 2 261 mm) in diameter – 3,000 lb (1 361 kg) capacity. Features rotating capability.

TG4000

Handles 54″ to 89″ (1 372 mm – 2 261 mm) in diameter tires – 4,000 lb (1 814 kg) capacity with manual swivel, tilt and rotate capabilities.

TG4000R

Offers 4,000 lb (1 814 kg) capacity for tires ranging from 34″ to 89″ (864 mm – 2 261 mm) in diameter. Features reversible teeth for added versatility, along with manual rotating function.

TG4000XL

Perfect for handling oversized construction equipment tires – 58″ to 95″ (1 473 mm – 2 413 mm) in diameter with a 4,000 lb (1 814 kg) capacity. Features manual swivel, tilt and rotate capabilities.

TG12000

Handles tires from 67″ – 120″ (1 702 mm – 3 048 mm) in diameter weighing up to 12,000 lbs (5 443 kg)! Features rotating capability via hydraulics.

Don’t let industrial tire changes derail your construction site projects. Contact us today to request a quote for the TireGrabber tire handler!

FAQs about the TireGrabber tire handler for construction sites

The TireGrabber is more than just a smart way to handle heavy tires used on articulated trucks, asphalt pavers, backhoes, dump trucks, telehandlers, forklift loaders, and graders – it’s a game changer that gives you an advantage on the job site.

- Safety first: Protect your crew from injuries. The TireGrabber tire handler enables a single operator to securely grip, lift, manipulate and change large equipment tires up to 12,000 lbs (5 443 kg) and 120” (3 048 mm) in diameter, safely.

- Time is money: Stop wasting time wrestling with heavy tires. The TireGrabber’s patented design lets you swap tires quickly and efficiently, keeping your project on schedule.

- Built to last: The TireGrabber isn’t afraid of tough jobs. Made from high-strength, tensile steel, it’s built to take a beating and keep on grabbing.

- Right for every rig: We offer five TireGrabber models (TG3000, TG4000, TG4000R, TG4000XL, TG12000) to handle all your tire sizes, from pick-ups to heavy machinery.

Yes! The innovative, patented design offers these features:

- Built like a bulldozer: The TireGrabber is constructed from super-strong, tensile steel. It’s engineer-certified and MPI-tested to ensure it can handle the toughest jobs.

- Three-arm advantage: Confidently pick up, pull off, swivel, swing and rotate heavy tires. The 45-degree rotation and three-arm grabber provides secure gripping, allows for easy alignment, balances the tire perfectly and makes tire changing effortless.

- Total control: Manual swivel and swing features give you complete control and confidence over tire positioning.

- Reversible option: The reversible teeth on the TG4000R model give you extra versatility on the job site.

The TireGrabber is engineered to accommodate a diverse range of tire sizes. Picking the right model TireGrabber is all about matching the tool to the tires on your construction vehicles and equipment. Here’s what you need to know:

- Measure up: Grab your tape measure and get the diameter of your biggest tires.

- Match your needs: Choose the TireGrabber that fits your tire size range:

- TG3000 and TG4000: 54″ – 89″ (1 372 mm – 2 261 mm) in diameter

- TG4000R: 34″ – 89″ (864 mm – 2 261 mm) in diameter (reversible teeth for wider range)

- TG4000XL: 58″ – 95″ (1 473 mm – 2 413 mm) in diameter (built for oversized tires)

- TG12000: 67″ – 120″ (1 702 mm – 3 048 mm) in diameter (built for tires weighing up to 12,000 lbs/5 443 kg)

Not sure which model is right for your crew? No problem! Contact us and talk to one of our TireGrabber specialists. They’ll help you find the perfect fit for your construction site.

You may also be interested in the TG Equipment Jack – the perfect complement to the TireGrabber system.